The Bimini made it onto the To-Do-List this morning. Actually its customised tensioning, which settled in after two seasons and I felt it was a bit loose in recent gusting wind conditions. As the dyneema ropes are made to length the only option was to cut a bit off the four adjustable tensioners. The little vice we have onboard is always handy for this kind of jobs. Got it completed before the sun took over and indoor activities kicked in.

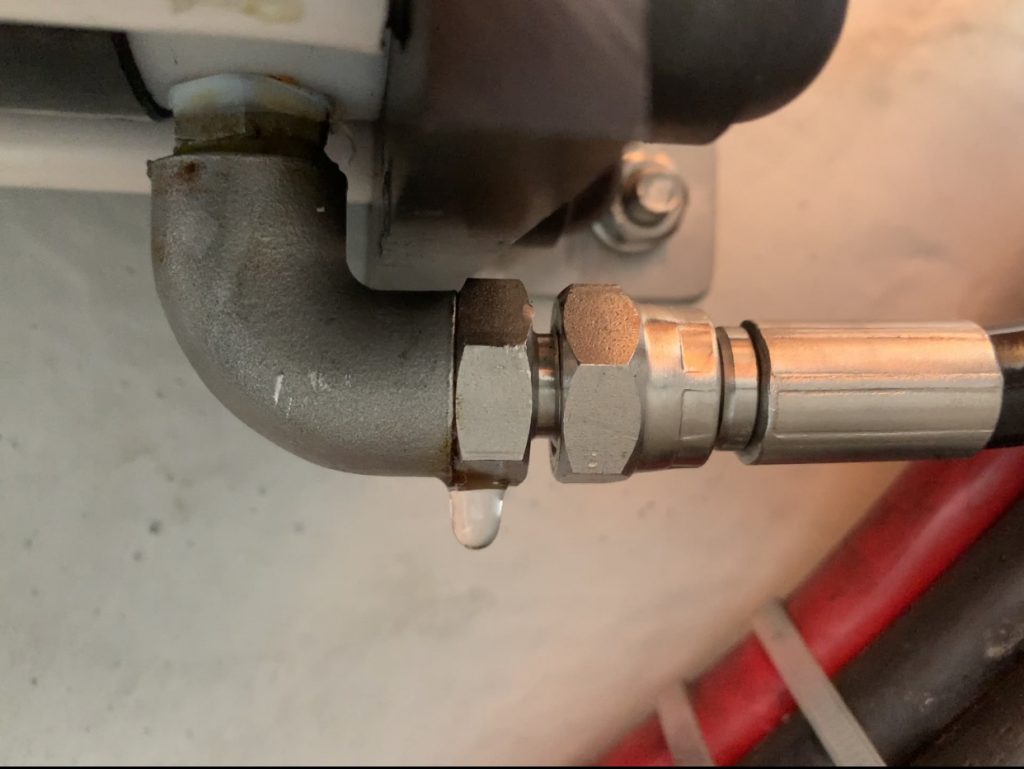

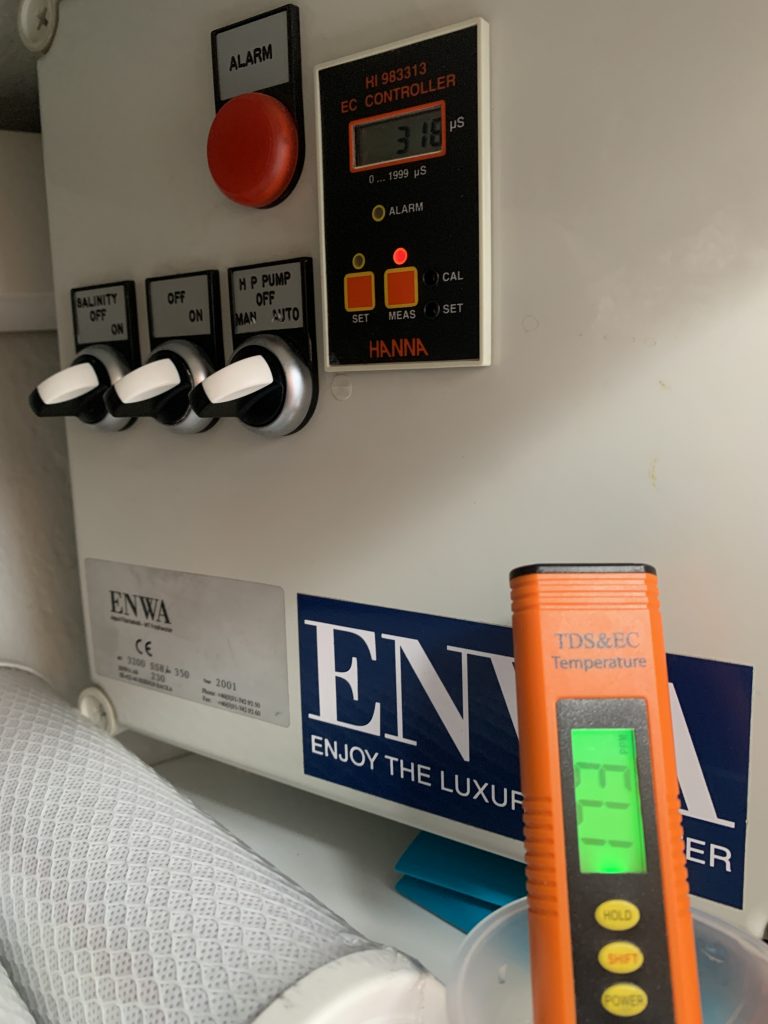

Martin from Hallberg-Rassy Parts did put in the extra effort and got a new compressor unit on its way this morning. It shall arrive coming Monday, latest. Cross fingers! Nevertheless we will try to get the current unit running again in which case the new one will be a good spare.

I already feel some pain operating with one fridge only and it is better to carry a spare unit than being with only one fridge for a longer period of time. This issue remains open.

Besides that I finlized the turnbuckles and same time lost one half cap of the screw cover to the sea. Damned, totally unnecessary but happened.

After a food inventory check, I jumped on the bike for Lidl in PDC and stocked up the pantry. I got a list from Susan and it’s long.

Over a glass of wine on SY Christina with Elke and Ulli we will call it a day.

Fair winds…

, that is not pleasant.

, that is not pleasant.

coach René mentioned to me to take it lightly as there is still some Calima dust in the air. Therefore I invited myself for a beer at Musa Bar before heading back to receive their lines.

coach René mentioned to me to take it lightly as there is still some Calima dust in the air. Therefore I invited myself for a beer at Musa Bar before heading back to receive their lines.